Starrett Holesaw helps you achieve cost savings and increase profits while delivering quality results

27 April 2023

31 October 2023

Read Time: 3 Mins | 7 April 2021

Following on from the launch of our new 3X POWER reciprocating blades we have had many people interested in ‘trying them out’. Which blade to choose is always a common question, so we’ve put together this handy blog to get you on the right path to cutting success.

Why use a reciprocating saw?

They are less laborious to use, offering ease of access in many applications, cut faster and more accurately than hand saws and offer a larger cut capacity compared to cutting discs. Higher levels of safety thanks to the reduction in vibration, noise and sparks, therefore less risk of fire.

Designed to cut all types of materials including wood, metal and plastics in solid and profile form, our new 3X POWER reciprocating blades are designed for numerous industries, and applications, including construction and engineering, for the dismantling of wood and metal structures, frameworks and the destruction of metal fabrications. They can also be used in the reclamation industry, pallet dismantling, vehicle repair and dismantling, fire and rescue for emergency extrication, as well as DIY and self-build.

How to identify the blade required

Within the 3X POWER range each of the blade’s feature a universal shank that is designed to fit any corded or cordless machine. These shanks are colour coded to enable easy identification of the blades cutting capability.

The colour code explains

To choose the correct blade follow our 4 easy steps:

Step One: What material are you cutting?

Example 1 – 50mm (2”) steel tube with a wall thickness of 4mm – you will choose a metal cutting blade, with a blue shank.

Example 2 – Timber solid material thickness 100mm – you will choose a wood cutting blade with a yellow shank.

Step Two: Blade length How to Calculate.

Measure the dimension/thickness of the material you wish to cut. Your cut section.

In this case we have 50mm steel tube.

Now we need to add 50mm for blade tip clearance, plus 25mm for the machine stroke to the cut section. (This additional 75mm is standard and needs adding to any cut section)

When added together the result is the blade length required; 125mm.

i.e. 50mm cut section + 50mm blade tip clearance + 25mm machine stroke = 125mm

Example 2 – Timber solid material thickness 100mm: cut section 100mm + 50mm blade tip clearance + 25mm machine stroke = 175mm blade length.

Step Three: TPI (teeth per inch) How to select.

Equally as important, we need to select the correct TPI and to do so, we’ve created this handy chart. For Example 1 below we reference the blue/metal section for our steel tube and as the wall thickness is 4mm, we can identify the correct TPI is 18.

For a solid material you would go on the material thickness. For a 50mm solid metal you would need an 18 TPI blade.

For Example 2, you would look at the yellow section for wood. There are two possible TPI choices: you will need to go to step four and utilise the blade length requirements.

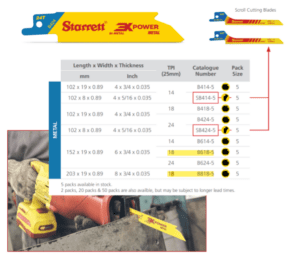

Step Four: Identifying the correct blade from the range

Now we know the correct blade length required and TPI, it’s simply a matter of identifying which product fits the bill.

For Example 1.

Looking at the metal product range. We need a blade that is 125mm long, with 18 TPI.

Our first choice would be B618 and the B818 our secondary option.

For Example 2.

Looking at the Wood product range. We need a blade that is 175mm long with either a 3 or 6 TPI.

Our first choice would be BT96 with either the BT123 or BT126 being the alternatives.

The Starrett team is here to help – CuttingSolutions

We hope this quick step-by-step blog as helped you understand how to choose the correct blade. However, should you still have questions, we have a dedicated Sales and Technical Support team on-hand, click this link and book a time slot convenient to you. Please do not hesitate to get in touch, we are here to help.

Back to AllDear Valued Distributors and Customers, For over six decades, Starrett has stood as a symbol of excellence within power ...

Read MoreWe are excited to announce Starrett’s participation as an exhibitor at EMO Hannover 2023, one of the most prestigious trade fairs ...

Read MoreBook a slot to discuss product application or information and speak directly with our professional Tech Team.

Book Now© The L. S. Starrett Company Limited 2024. All rights reserved.

Website made with by GRO.